The dawn of the American lithium industry has arrived in Southern Arkansas. With this opportunity comes a water problem — and we have the solution.

Hidden in Arkansas’s Smackover Formation is a generational opportunity. Not in the form of gold or diamonds, but lithium. The technological cornerstone of this revolution is Direct Lithium Extraction (DLE), but capitalizing on this boom hinges on efficiently and sustainably managing the complete water lifecycle, including pre-treating challenging brines, processing massive volumes, and ensuring environmentally sound reinjection.

Fortunately, there is an award-winning team of water treatment experts with patented technology and a holistic portfolio of services designed to harness Arkansas's lithium future sustainably and profitably. And the best part: We have called Arkansas home for generations.

We are Menen Group, and we are here for good.

The Smackover Formation represents a paradigm shift in critical minerals, positioning Arkansas at the epicenter of America's domestic lithium supply chain.

History in the Making

A New Frontier for Water Solutions

5-19M

Metric Tons of Lithium

671

mg/L Peak Concentration

600

Miles Formation Length

19.6%

DLE Market CAGR

-

The Smackover Formation contains lithium dissolved in hot, high-salinity brine trapped in Jurassic-era limestone. With concentrations exceeding 400 mg/L and recent discoveries showing up to 671 mg/L, these grades rival South America's "Lithium Triangle."

Unlike arid regions, Arkansas doesn't face water scarcity issues, making closed-loop water management systems more feasible and sustainable.

-

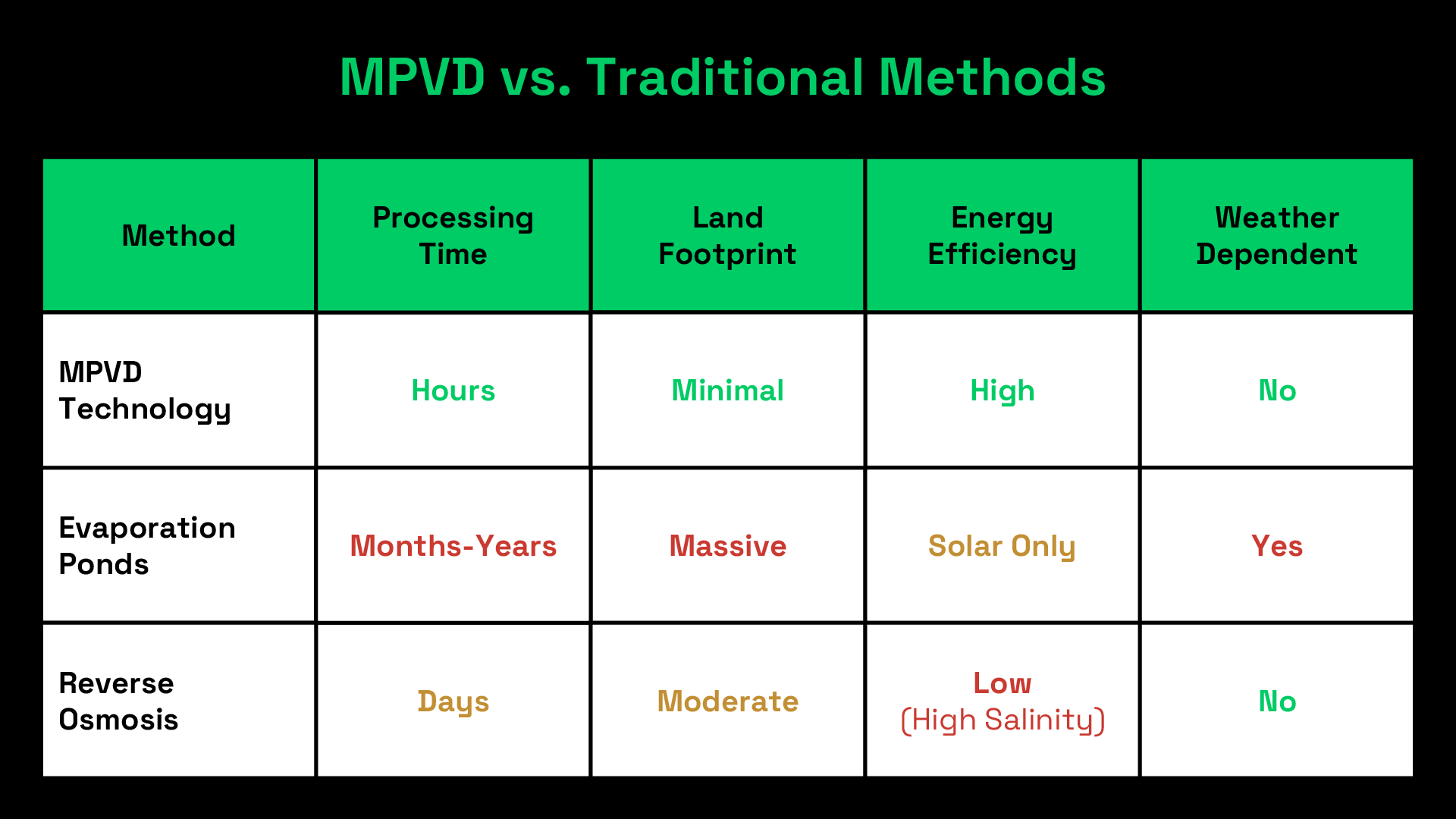

DLE technologies offer a faster, more efficient alternative to traditional solar evaporation. These advanced water treatment processes can produce lithium in hours instead of months, with a much smaller environmental footprint.

Adsorption

Selective lithium capture using specialized sorbents

Ion Exchange

Resin-based lithium extraction processes

-

Success depends on managing complex water lifecycles: pre-treating challenging brines, processing massive volumes, and ensuring environmentally sound reinjection. This creates opportunities for both primary lithium extraction and secondary municipal infrastructure growth.

Key Takeaways

The Smackover Formation

World-Class Resource: The Smackover Formation contains 5-19M metric tons of lithium with high concentrations comparable to South America.

Technology-Driven: Extraction relies on Direct Lithium Extraction (DLE), advanced water treatment technologies faster and more sustainable than traditional methods.

Water Challenge at Core: Success depends on managing complex water lifecycles, processing massive volumes, and ensuring environmentally sound reinjection.

Dual Opportunity: Creates demand for both primary lithium extraction solutions and secondary municipal infrastructure growth.

"The Smackover is sort of the right time, the right place, and the right geology combined."

Erik Pollock | University of Arkansas Geoscientist, Arkansas Research

It all starts with cost-effective, sustainable extraction and concentration — delivered by WATR™ Labs MPVD Technology.

Patented Innovation

WATR™ Labs MPVD Technology

Multi-phase Vacuum Desalination (MPVD). A breakthrough solution for high-salinity brine treatment, protected by U.S. Patent No. 11,878,919 B1.

How MPVD Works

MPVD leverages reduced pressure to lower the boiling point of brine, enabling efficient water vapor separation at lower temperatures than traditional thermal methods. This significantly reduces energy consumption while achieving higher concentration factors.

The "multi-phase" staged process prevents premature salt precipitation and scaling, common failure points in other high-salinity treatment systems.

-

Reduced temperature operation saves energy costs

-

Superior concentration factors vs. competitors

-

Smaller footprint than evaporation ponds

-

Increases lithium concentration before primary DLE

-

Concentrates dilute lithium solutions to high-purity product

-

Arkansas-developed technology for worldwide deployment

-

Enhanced Recovery

MPVD significantly increases overall lithium recovery rates by efficiently concentrating post-DLE solutions, maximizing sellable product from the same brine volume.

✔ Higher purity lithium concentrate

✔ Premium pricing potential

✔ Reduced refining costs

-

Cost Efficiency

Multi-faceted cost reduction through lower energy requirements, compact design, and water recovery capabilities

✔ Reduced OPEX through energy savings

✔ Lower CAPEX with smaller footprint

✔ Water reuse reduces costs

-

Sustainability

Zero Liquid Discharge capability positions projects as leaders in sustainable resource extraction with minimal environmental impact.

✔ Maximum water recovery

✔ Minimal waste generation

✔ Enhanced social license

Ready to Learn More About MPVD?

Discover how our patented technology can enhance your lithium extraction operations

Menen’s integrated water platform provides value throughout the lithium battery supply chain.

Vertically Integrated Solutions

Beyond Extraction: Complete Value Chain Coverage

Water plays a vital role from exploration through battery cell manufacturing, and Menen’s integrated water platform provides value, not only at extraction facilities, but throughout the entire lithium battery supply chain. Our expertise extends across the entire lithium value chain, from brine exploration to battery manufacturing. A comprehensive partner for Arkansas's lithium ecosystem.

-

Resource Exploration

Advanced water quality analysis with HIDRATE™ for brine characterization and identifying optimal extraction zones.

✔ Lithium concentration mapping

✔ Brine chemistry analysis

✔ Extraction zone optimization

-

Extraction & Purification

Core MPVD technology and DRROP™ modular systems for brine pre-concentration, lithium purification, and ZLD operations.

✔ Patented MPVD technology

✔ Modular DRROP™ systems

✔ Zero Liquid Discharge

-

Battery-Grade Production

Water-intensive conversion of lithium salts to battery-grade lithium hydroxide with high-purity water supply and wastewater treatment.

✔ High-purity water supply

✔ Chemical process support

✔ Wastewater treatment

-

Battery Cell Assembly

Ultrapure water requirements and complex wastewater management for full-scale battery manufacturing operations.

✔ Ultrapure water systems

✔ Manufacturing support

✔ Complex wastewater management

Complete Partnership

Single partner for the entire lithium value chain, reducing complexity and ensuring seamless integration.

Ecosystem Development

Supporting Arkansas's transformation into a complete lithium ecosystem from resource to finished product.

Scalable Solutions

Modular, scalable technologies that grow with your operations from pilot to full commercial scale.

The Power of Synergy: Integrated Platform

-

DRROP™ Pods

Modular treatment units

-

HIDRATE™ Sensors

Continuous monitoring

-

LOGR™ AI

Intelligent optimization

-

WATR™ Labs MPVD

Core concentration technology

This creates a self-optimizing, intelligent water management platform that maximizes lithium production, minimizes environmental impact, and delivers the lowest possible cost of operation. The same integrated platform extends to manage significant water and wastewater needs of co-located battery materials or cell manufacturing plants, offering a true 'brine-to-battery water management solution.'

Holistic Solutions Portfolio

Complete Water Lifecycle Management

Our integrated suite of solutions addresses every aspect of lithium production water management, from rapid deployment to AI-powered optimization.

Treatment-as-a-Service

DRROP™ Pods

Containerized, modular water treatment systems for rapid deployment and flexible scaling

-

On-site testing of DLE flowsheets with actual brine

-

Modular units for initial brine conditioning

-

✔ CAPEX to OPEX conversion reduces upfront investment

✔ Accelerated project timeline from concept to production

✔ Flexible scaling up or down as operations evolve

Water Quality Monitoring

HIDRATE™ Sensors

Advanced monitoring solution providing real-time water quality data and compliance assurance

-

Real-time monitoring of incoming brine composition

-

In-line sensors throughout treatment train

-

✔ Proactive process optimization for higher recovery rates

✔ Continuous compliance monitoring and auditable data

✔ Environmental stewardship and social license protection

AI-Powered Process Modeling

LOGR™ AI

Intelligent automation platform that creates a "digital twin" of water treatment facilities for optimal performance

-

Forecast performance impacts from brine chemistry changes

-

AI-driven adjustments for maximum lithium recovery

-

Intelligent management of complex multi-stream facilities

-

✔ Peak efficiency operations with reduced OPEX

✔ Proactive decision-making reduces costly downtime

✔ Consistent, reliable production optimization

-

Real-time facility modeling combines sensor data with predictive algorithms for intelligent automation

Elevates operations from manual control to intelligent automation

Water Innovation Hub

WATR™ Labs

A cutting-edge research and development hub tackling the water treatment questions of today in order to solve the problems of tomorrow.

-

Industry experts tasked with researching, developing and, ultimately, solving current treatment issues or, in some instances, averting them altogether

-

An elite team of unbiased, objective engineers, biologists and technicians looking to find, guide and inspire the next generation of problem solvers within the water space

-

Capable of assisting and expediting companies, industries and municipalities with pressing treatment challenges through research, development and knowledge sharing

The best water treatment technology in the Natural State is from the Natural State.

Proven Innovators with Arkansas Roots

Menen Group was founded in the Heartland with a clear mission: to solve pressing water challenges. Our tagline, "evil geniuses for good," captures our ethos of applying world-class technical expertise with an agile, disruptive mindset.

Our leadership team previously built Fayetteville-based BlueInGreen from startup to successful acquisition by a large, publicly traded company for over 20x EBITDA, demonstrating full-cycle expertise in innovation, commercialization, and value creation.

Our vision extends beyond Arkansas's borders. We intend to leverage our success in the Smackover to establish Arkansas as a global exporter of advanced water treatment technology for the lithium industry.

By developing and perfecting these solutions here, we create a sustainable, high-value export that enhances Arkansas's position as a world leader in the energy transition, generating long-term economic benefits that transcend the initial resource extraction.

150+

International Installations

$200M+

M&A Activity Managed

Local Commitment & Economic Impact

-

Local Operations

Expanding operations in Arkansas, creating high-value jobs for engineers, technicians, and manufacturing personnel while building a local ecosystem.

-

Strategic Partnerships

Active partnerships with Arkansas companies for fabrication and supply, plus collaboration with non-profits and academic institutions like the University of Arkansas.

-

Economic Development

Committed to being a key driver of Arkansas's lithium boom, ensuring wealth generated from natural resources is reinvested in the state's people and economy.

ALTA Program Selection

Our application for Cohort #2 of the Arkansas Lithium Technology Accelerator (ALTA) is the single most important catalyst for our go-to-market strategy. ALTA is America's first accelerator dedicated to lithium innovation, backed by Standard Lithium, the Walton Family Foundation, and the University of Arkansas.

Direct Access

Structured engagement with major lithium players including Standard Lithium, ExxonMobil, and Equinor

Accelerated Development

Fast-track from lab-proven technology to commercially deployed, revenue-generating solution

Investment Magnet

Industry-vetted technology creates compelling, time-sensitive investment opportunity

-

Local Expertise

Deep understanding of Arkansas industrial culture and regulations

-

Proven Team

Seasoned operators with successful exit track record

-

ALTA Validation

Industry-backed accelerator program participation

-

Local Investment

Committed to Arkansas economic development and job creation

Let’s Get To Work.

Ready to explore how Menen Group can transform your lithium extraction operations? Let's discuss your water management challenges and opportunities.

Contact

Menen is here to answer your questions about our patented MPVD technology, holistic solutions portfolio, and how we can support your Arkansas lithium projects.

Address

965 E Robinson Ave

Springdale, AR 72764

Phone

(479) 323-1654

Email

info@menengroup.com